MIL-A-8625F Type II Class 1

Type II Class 1 anodizing is the most common type of anodizing for aluminum and offers a moderate thickness of oxide layer, typically ranging from 0.0002 to 0.001 inches. This process provides excellent corrosion resistance while maintaining a natural or clear finish, making it suitable for a wide range of applications where both protection and aesthetic appearance are important.

MIL-A-8625F Type II Class 2

Type II Class 2 anodizing involves the formation of a thicker oxide layer (typically 0.0003 to 0.0015 inches) compared to Type II Class 1 anodizing. This increased thickness enables the application of a wide variety of vibrant colors through dyeing, making Type II Class 2 anodizing a popular choice for decorative and architectural applications that require both enhanced corrosion resistance and a range of color options. Click here for a visual sample of our standard dyes.

MIL-A-8625F Type III Class 1

Type III Class 1 anodizing involves the formation of a considerably thicker and harder oxide layer (typically 0.001 to 0.002 inches) compared to Type II anodizing. This increased thickness and hardness provide exceptional wear resistance and durability, making Type III Class 1 anodizing ideal for applications requiring robust protection, such as aerospace, military, and industrial components.

MIL-A-8625F Type III Class 2

In Type III Class 2 anodizing, the thicker oxide layer (typically 0.001 to 0.002 inches) is contributes to a stronger gray hue. The gray oxide layer acts as a base that enhances the depth and richness of the dye colors applied. By dyeing the gray oxide layer, a broader spectrum of darker and more intense colors can be achieved.

MIL-A-63576A Type I and other Teflon Specifications

While MIL-A-63576A is a retired specification, we can still perform the process as well as apply an Anoslick coating to any anodize coating.

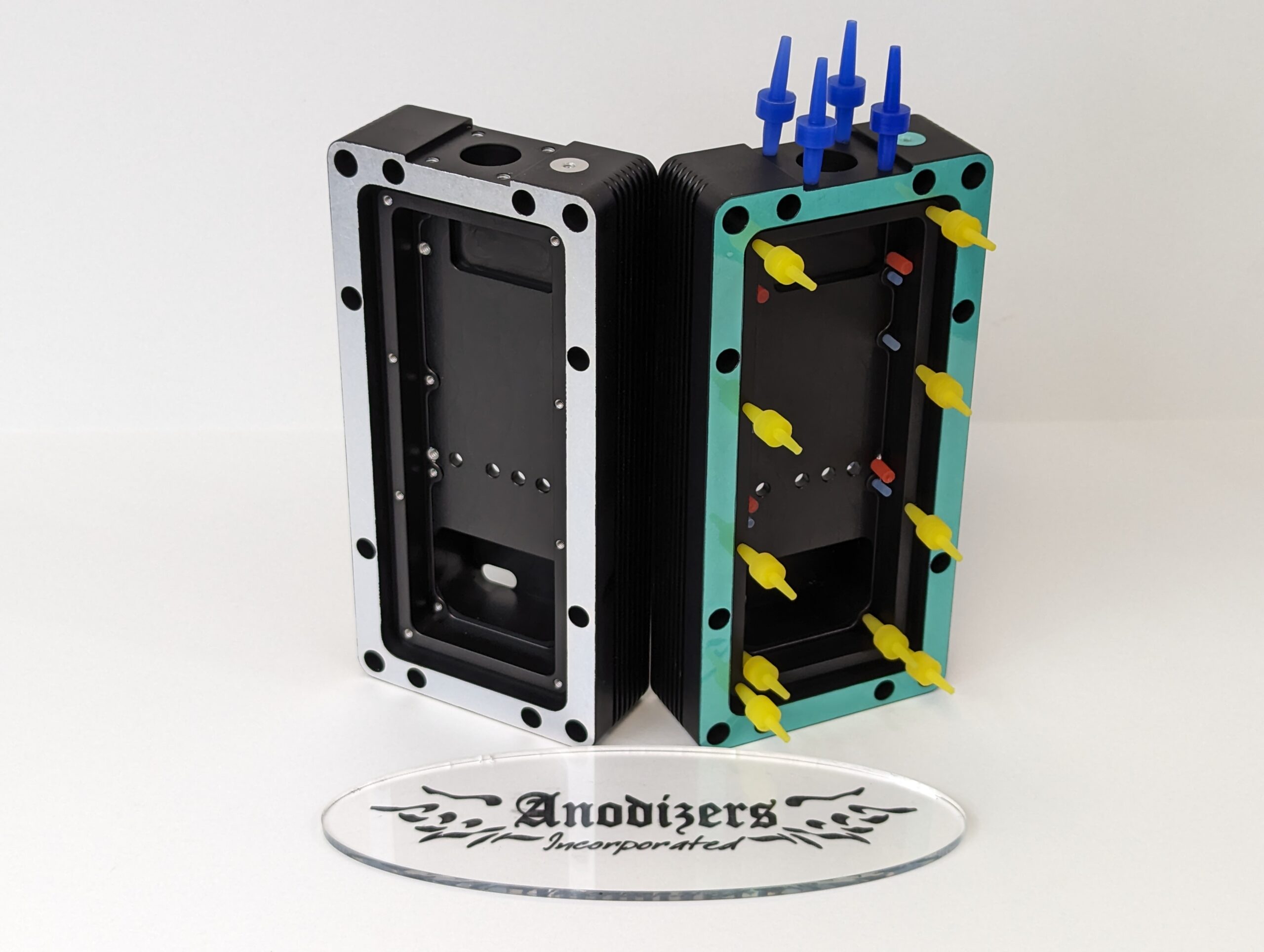

Masking

We have the capabilities to mask parts prior to anodizing using: tape, plugs, paint, and other custom methods. We can also utilize MIL-DTL-5541 Type I or Type II for masked areas.

Other Specification?

We have found that most other anodizing specifications are based around MIL-A-8625F. If you are unsure, send us a copy of the specification and we can review it.

Tank Specifications:

- Anodizing Tank Dimensions – 80″ Length x 12″ Width x 29″ Depth

Ready to begin?

Unlock your project’s success with our expert services and collaborative approach.